In today’s fast-paced industrial landscape, efficiency is key. CIMC Pteris Company takes the lead with its cutting-edge belt driven conveyor systems. This article explores the significance and advantages of these state-of-the-art solutions.

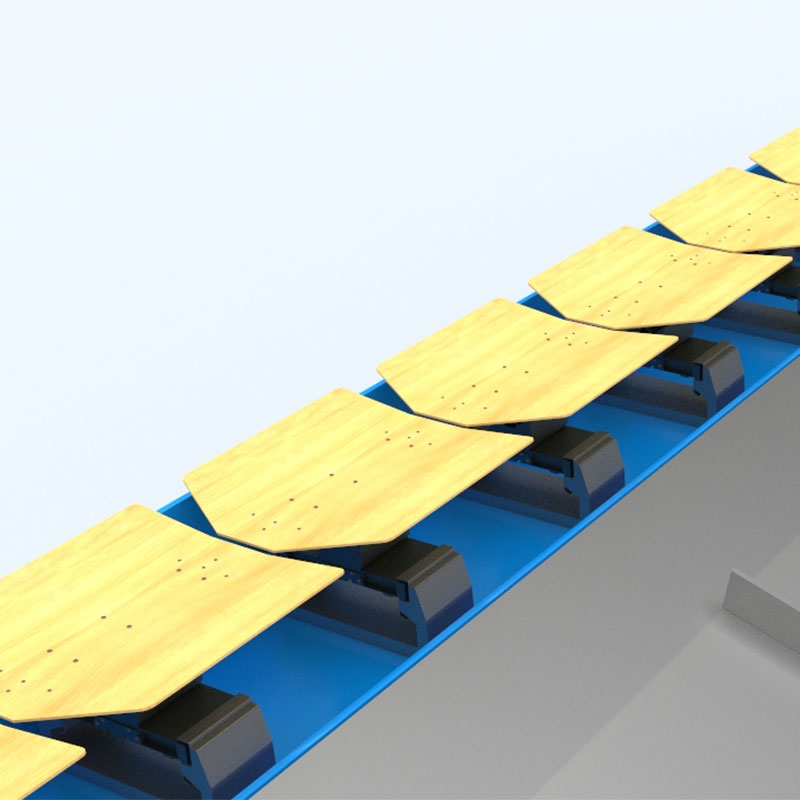

Unveiling CIMC Pteris Company’s Belt Driven Conveyors

CIMC Pteris Company’s belt driven conveyors are engineered to redefine the efficiency and productivity of material handling operations. Let’s delve into the key features that make these systems indispensable for modern businesses.

Streamlined Material Handling

A standout feature of these conveyors is Our ability to optimize material handling processes. we maintain a consistent flow of materials, eliminating bottlenecks and enhancing operational efficiency. This leads to cost savings and increased productivity.

Optimized Space Utilization

Space constraints in our facility were a challenge, but these conveyors have proven to be a space-saving solution. our compact design and ability to move materials efficiently within our existing layout have allowed us to maximize our facility’s space utilization, optimizing our operations in the process.

Integration with Automation

The conveyors seamlessly integrate with our existing automation systems. This compatibility has enabled us to implement a higher degree of automation in material handling, resulting in reduced labor costs and enhanced operational efficiency. The synergy between automation and these conveyors is driving productivity to new heights.

Customization for Unique Needs

The first step in customizing a sortation system is understanding the specific needs of a warehouse. This involves analyzing factors such as volume of products handled, size and weight of products, desired sorting accuracy, throughput speed, available space, and budget constraints.

CIMC Pteris’ experts work closely with warehouse managers to gain a deep understanding of their requirements. They conduct on-site visits to assess the current operations and identify areas for improvement.

Based on the analysis of warehouse requirements, CIMC Pteris’ team designs a tailored solution that addresses all the pain points identified during the assessment process. This includes selecting the most suitable type of sorter (e.g., tilt-tray or cross-belt), determining its size and configuration, and integrating other necessary components such as diverts, chutes, sensors, and controls.

We appreciate that no two businesses have the exact same material handling requirements. CIMC Pteris’ Belt Driven Conveyors understand this too. These systems are highly customizable, allowing us to tailor them to our unique needs. This adaptability empowers us to address specific challenges and further boost our operational efficiency.

Conclusion

CIMC Pteris Company’s Belt Driven Conveyors have redefined how we approach material handling. we offer enhanced flexibility, contribute to sustainability, prioritize safety, optimize space utilization, integrate seamlessly with automation, and provide customization options. In a world of diverse material handling challenges, these conveyors are our key to elevating efficiency and ensuring our operations are not only cost-effective but also future-proof.

If you’re seeking to enhance your material handling processes, we encourage you to explore CIMC Pteris Company’s Belt Driven Conveyors. our adaptability and multi-faceted advantages can be the solution your business needs to reach new heights in material handling efficiency.