In today’s fast-paced and highly competitive business environment, optimizing warehouse operations is crucial for companies aiming to stay ahead. CIMC Pteris, a leading provider of custom warehouse automation solutions, offers an innovative approach with their Automated Warehouse Management System. By leveraging advanced technologies and intelligent automation, our company revolutionizes the way warehouses operate, enhancing efficiency, accuracy, and productivity.

The Advantages of an Automated Stacker

Automation and Efficiency: At CIMC Pteris, we understand the importance of streamlining loading and unloading operations in warehouses. Our Automated Stacker takes center stage in this endeavor, seamlessly handling the movement of goods with precision and speed. By automating these processes, we eliminate the need for manual labor, leading to improved efficiency and enhanced operational accuracy.

Large Loading Capacity: The Automated Stacker boasts a high loading capacity, allowing it to handle various goods with ease. Its stacking height further maximizes storage space, enabling warehouses to efficiently utilize their available area. With CIMC Pteris’ Automated Stacker, you can optimize your warehouse’s storage capacity while ensuring the safe handling of goods.

Versatile Applications: One of the key strengths of CIMC Pteris’ Automated Stacker is its versatility. It is well-suited for a wide range of applications across different industries. Whether you operate a warehouse, factory, or port, our Automated Stacker can adapt to your specific needs. Its flexibility enables efficient handling of multiple types of goods, making it an invaluable asset in your operations.

Enhancing Warehousing Efficiency with Robot (DE)palletizing System

Automated Warehouse Access: The Robot (DE)palletizing System provided by CIMC Pteris revolutionizes warehouse access and retrieval operations. Running along high-rise shelf warehouse tracks, this system offers efficient and seamless access to unit goods. By eliminating the need for manual intervention, it reduces human error and enhances overall productivity.

Customizable Solutions: CIMC Pteris understands that every warehouse has unique requirements. That’s why our Robot (DE)palletizing System offers customizable solutions tailored to your specific needs. Whether it’s optimizing palletizing processes or integrating with your existing automated warehouse management systems, we provide personalized solutions that enhance productivity and quality.

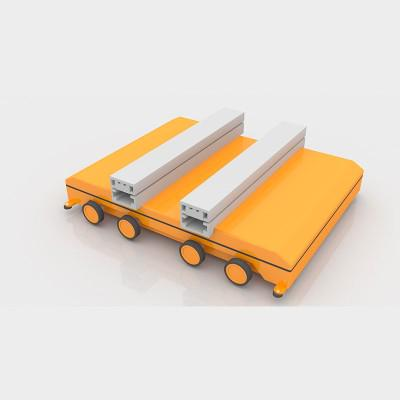

Optimal Space Utilization with the Four-Way Shuttle and Multi-Layer Shuttle Systems

Efficient Space Usage: CIMC Pteris’ Four-Way Shuttle System is designed to maximize space utilization in warehouses. By driving along vertical and horizontal orbits, it provides access to specified cargo positions, ensuring optimal space usage. This automated warehouse management system optimizes storage capacity, allowing warehouses to accommodate more goods while maintaining efficient operations.

Multi-Level Storage: The Multi-Layer Shuttle System takes warehouse space utilization to new heights. It efficiently places goods between different levels and heights of a three-dimensional warehouse. By utilizing hoisting capabilities, this system ensures optimal space usage, enabling warehouses to make the most of their vertical storage potential.

Conclusion

In conclusion, CIMC Pteris’ Automated Warehouse Management System is a game-changer for companies seeking to streamline their warehouse operations. With our Automated Stacker, Robot (DE)palletizing System, and innovative shuttle systems, we offer customizable solutions that enhance efficiency, accuracy, and space utilization. Embrace the future of warehousing with CIMC Pteris and experience the transformative power of automation in your operations.