Sortation conveyors play a vital role in streamlining the logistics and distribution process for businesses. With our advanced functionality, CIMC Pteris has developed a reliable and efficient sortation conveyor system that revolutionizes the sorting process. This article will explore the application method and the key features that enable CIMC Pteris sortation conveyors to achieve accurate sorting.

Application Method of CIMC Pteris Sortation Conveyors

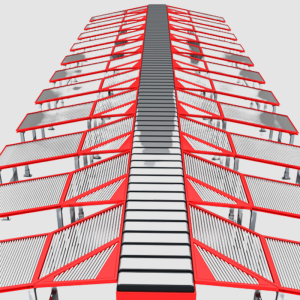

CIMC Pteris sortation conveyors are designed with precision and efficiency in mind. The entire equipment is driven by a sprocket chain, powered by a deceleration motor in the driving section. This setup ensures smooth operations and consistent performance. The sortation conveyors operate at a constant high speed within a closed-loop track, allowing for uninterrupted sorting processes.

Achieving Accurate Sorting with CIMC Pteris Sortation Conveyors

To ensure accurate sorting of goods, CIMC Pteris employs innovative features in their sortation conveyor system. One of these features is the concept of a dynamic window for sorting carriers. Each item to be sorted is assigned a sorting carrier, which acts as a dynamic window. The system automatically locates and tracks the real-time position of each window, ensuring precise sorting.

Real-time tracking and positioning are essential for efficient sorting. CIMC Pteris sortation conveyors utilize advanced technology to continuously monitor and update the position of each window. This real-time tracking allows for quick adjustments and ensures that each item is directed to its designated location accurately.

Another key feature of CIMC Pteris sortation conveyors is the lateral movement of the belt conveyor. When the goods reach the unloading chute corresponding to their specified address, the controller sends a signal. In response, the belt conveyor runs laterally, directing the goods into the appropriate unloading chute. This lateral movement enables precise sorting and minimizes errors in placement.

Accuracy is further enhanced by the signal-based unloading chute system. The controller sends a signal to indicate the specific address for unloading. This signal ensures that the goods are sorted into the correct unloading chute with precision and efficiency. CIMC Pteris sortation conveyors’ signal-based unloading chute system eliminates confusion and enhances the overall sorting accuracy.

Conclusion

To sum up, CIMC Pteris sortation conveyors offer a reliable and efficient solution for businesses seeking accurate sorting capabilities. With our application method driven by a sprocket chain and deceleration motor, as well as constant high-speed operation within a closed-loop track, these conveyors ensure smooth and consistent performance. The dynamic window concept, real-time tracking and positioning, lateral belt conveyor movement, and signal-based unloading chute system enable CIMC Pteris sortation conveyors to achieve precise sorting. Invest in CIMC Pteris sortation conveyors to optimize your sorting processes and enhance operational efficiency.