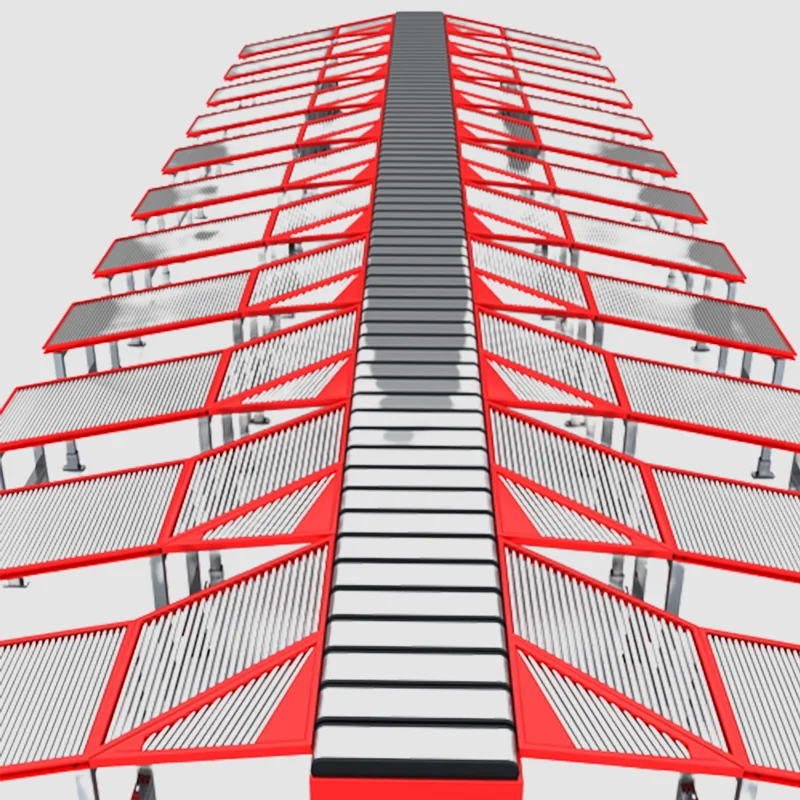

In today’s fast-paced world of express delivery logistics, efficiency is key. CIMC Pteris‘ Narrow Belt Sorter is revolutionizing sorting operations by streamlining processes and optimizing productivity. With its dynamic window concept and sprocket chain-driven system, this advanced sortation conveyor ensures real-time tracking and accurate sorting of individual goods.

Streamlining Operations with the Narrow Belt Sorter

The Narrow Belt Sorter’s application method is simple yet effective. Each sorting carrier corresponds to a dynamic window that tracks the real-time position of the items. When the goods reach the unloading chute with the specified address, the controller sends a signal, and the belt conveyor swiftly moves laterally to sort the goods accurately. This automated process eliminates errors and reduces the need for manual intervention.

The benefits of the Narrow Belt Sorter are remarkable. Improved sorting accuracy ensures that each item reaches its intended destination, reducing the risk of errors and customer dissatisfaction. By automating the sorting process, labor costs are significantly reduced, allowing companies to allocate their resources more efficiently. The constant high-speed operation of the sprocket chain-driven system optimizes productivity, enabling express delivery logistics providers to meet tight deadlines and exceed customer expectations.

Boosting Productivity with the Flip Sorter

Baggage sorting in airports and logistics centers requires precision and speed. CIMC Pteris’ Flip Sorter is designed to automate the sorting, tracking, and identification of baggage, revolutionizing the industry with its innovative technology and exceptional performance. With its flexible layout and energy-efficient design, the Flip Sorter enhances productivity and accuracy in baggage handling operations.

The application method of the Flip Sorter is straightforward yet highly effective. Each cargo is loaded onto a single pallet and distributed through scanning equipment. As the cargo reaches the corresponding grid port, the tilting motor activates, tipping the pallet and allowing the cargo to slide down into the designated grid port. This automated process ensures efficient sorting without compromising speed or accuracy.

Enhancing Accuracy with the Cross-Belt Sorter

Accuracy is paramount in express delivery logistics. CIMC Pteris’ Cross-Belt Sorter is designed to enhance accuracy and efficiency by utilizing advanced technology and a closed-loop system. With an infeed station, scanning mechanisms, and a belt conveyor, this sortation conveyor ensures precise sorting and unloading of goods.

The application method of the Cross-Belt Sorter is a well-engineered process that guarantees accurate sorting. The infeed station guides the goods to the carrier, while the driving mechanism moves multiple carriers connected in series along the closed loop. The scanning mechanism determines the final destination, triggering the belt conveyor on the carrier to unload the goods into the corresponding chute.

Conclusion

In conclusion, CIMC Pteris’ sortation conveyors, including the Narrow Belt Sorter, Flip Sorter, and Cross-Belt Sorter, are transforming logistics operations by enhancing efficiency, accuracy, and productivity. With our innovative technology, customizable solutions, and commitment to customer success, we are the ideal partner for companies seeking to streamline their express delivery logistics and baggage handling processes. Contact CIMC Pteris today to discover how our sortation conveyor solutions can revolutionize your operations and drive your business forward.