In the current ferocious competitive market, streamlined logistics processes are essential to maintain competitiveness. Manual warehouse operations can be time-consuming and expensive, leading to errors, inefficiencies, and a lack of agility. As a result, more companies are turning to warehouse automation systems to enhance their operations. One such solution provider is Pteris Global, an integrated supplier that provides comprehensive solutions for the logistics industry. In this article, we will explore the benefits of warehouse automation systems and how Pteris Global can help optimize warehouse operations.

Increased Efficiency and Productivity

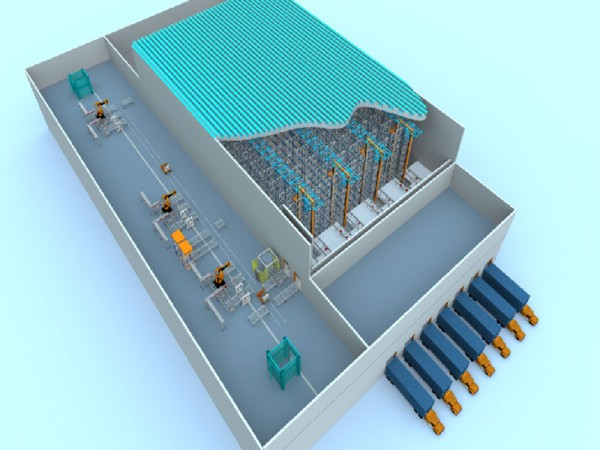

Automated systems minimize manual labor and streamline the warehouse management process. This results in increased efficiency and productivity, as tasks that would take hours or days to complete manually can be accomplished in a fraction of the time using automation technology. With Pteris Global’s solutions, like automated storage and retrieval systems (AS/RS), conveyors, and automated guided vehicles (AGVs), warehouses can handle large volumes of goods quickly and accurately. Such systems can also be customized to meet specific requirements, reducing the chance of errors and delays.

Improved Accuracy and Reduced Errors

Manual operations are often prone to human error, leading to mistakes in order picking, inventory management, and other tasks. Automated systems, on the other hand, use technologies like sensors, cameras, and barcode scanners to ensure accuracy at every stage of the process. Data can be captured and recorded in real-time, making it easier to track inventory levels, monitor shipment status, and manage returns. By reducing errors, businesses can improve customer satisfaction levels and reduce costs associated with returns or product recalls.

Greater Safety and Security

Warehouse automation systems can improve the safety and security of the warehouse environment. With AGVs and conveyors handling heavy lifting, workers can avoid repetitive strain injuries and other physical hazards. Additionally, automated systems can provide better visibility and control over the warehouse, reducing the risk of theft, damage, or loss of goods. Pteris Global’s solutions incorporate advanced safety features like collision avoidance systems and emergency stop buttons for increased safety.

Flexibility and Scalability

Automated systems can be tailored to meet the specific needs of a business and can accommodate changes in volume, product mix, or order complexity. Businesses can also scale up or down as needed without having to invest in additional labor or equipment. Pteris Global’s AS/RS system, for example, can be customized to fit varying warehouse dimensions, product sizes, and weight capacities. Its modular design allows businesses to expand or reconfigure their warehouse space easily.

Cost Savings

While the initial investment in automation technology can be significant, the long-term benefits often outweigh the costs. Automated systems reduce labor costs and the need for manual intervention, resulting in lower operating expenses. Additionally, automated systems can improve inventory accuracy, reducing the chance of overstocking or stockouts, which can result in lost sales or outdated inventory. By optimizing the warehouse layout and workflow, businesses can also save on energy costs, space utilization, and maintenance expenses.

Conclusion

The benefits of warehouse automation systems are clear: increased efficiency and productivity, improved accuracy, greater safety and security, flexibility, scalability, and cost savings. Pteris Global is an integrated supplier that provides comprehensive solutions for the logistics industry, including warehouse automation systems. With its focus on innovation, quality, and customer satisfaction, Pteris Global can help businesses streamline their operations and gain a competitive edge in today’s fast-paced business landscape.