Warehouse automation systems have become essential for businesses across various industries, enabling them to overcome challenges and streamline their operations. CIMC Pteris, a renowned provider of advanced warehouse automation solutions, offers cutting-edge technologies that revolutionize the way companies handle their logistics and storage. In this article, we will explore the challenges in warehouse automation, showcase two successful case studies, and highlight the advantages of CIMC Pteris’ warehouse automation systems.

Challenges in Warehouse Automation

- Overcoming Automatic Sorting Difficulties: Automating the sorting process presents significant challenges due to the diverse range of products and their specific requirements. CIMC Pteris addresses this challenge by developing intelligent sorting algorithms and leveraging advanced technologies to ensure accurate and efficient sorting in various industries.

- Achieving Fully Automatic Connection: Establishing seamless connectivity between workshops and warehouses is crucial for efficient operations. CIMC Pteris’ warehouse automation systems enable real-time data exchange and communication, ensuring a fully automatic connection that enhances productivity and reduces manual intervention.

- Handling Products with Different Specifications: Warehouses often deal with products of varying sizes, shapes, and specifications. CIMC Pteris’ solutions are designed to handle this diversity by providing customizable solutions that can adapt to different product requirements. Additionally, the company specializes in off-site loading, simplifying the logistics process and improving overall efficiency.

Advantages of CIMC Pteris’ Warehouse Automation Systems

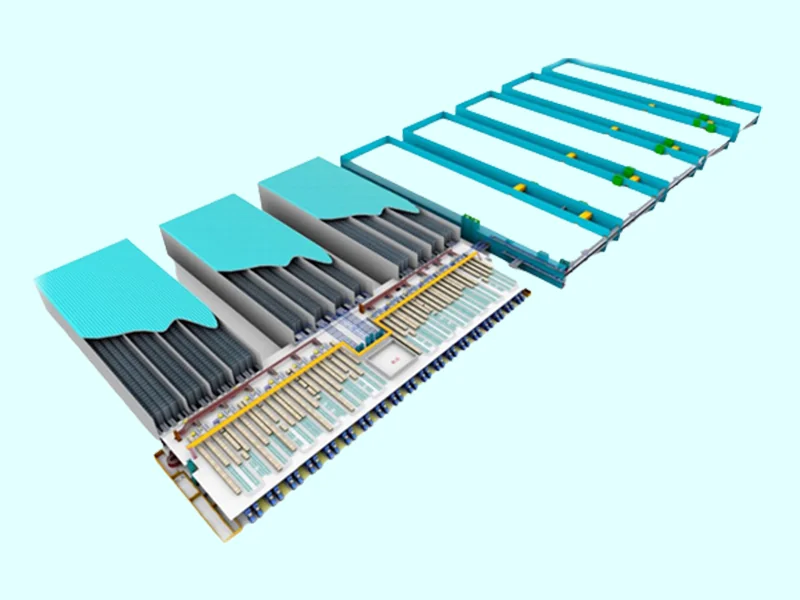

- Improved Space Utilization and Supply Chain Efficiency: CIMC Pteris’ warehouse automation systems optimize space utilization by implementing innovative storage solutions such as pallet-type three-dimensional storage systems and material box-type three-dimensional storage systems. These technologies maximize storage capacity, reduce warehouse footprint, and enhance supply chain efficiency.

- Reliable and Accurate Handling of Goods: CIMC Pteris’ solutions prioritize precision and reliability, ensuring that goods are handled with utmost care and accuracy. With advanced automated technologies, our systems minimize errors and reduce the risk of damages during the handling process.

- Customized Solutions for Diverse Warehouse Automation Needs: CIMC Pteris understands that each warehouse has unique requirements. Our company offers customized solutions tailored to meet the specific needs of different industries and businesses. By closely collaborating with clients, we design and implement warehouse automation systems that align with their workflows and optimize their operations.

Conclusion

In conclusion, CIMC Pteris is a leading provider of warehouse automation systems that streamline operations and enhance efficiency in various industries. By overcoming challenges in automatic sorting, achieving seamless connection, and handling products with different specifications, our company ensures smooth and optimized warehouse operations. With improved space utilization, reliable handling of goods, and customized solutions, CIMC Pteris’ warehouse automation systems empower businesses to stay ahead in today’s competitive market. Investing in CIMC Pteris’ warehouse automation systems is a strategic move that propels companies towards improved productivity, accuracy, and profitability. Experience the advantages of cutting-edge warehouse automation technologies and unlock the full potential of your warehouse operations with CIMC Pteris as your trusted partner.