Are you tired of costly errors and inefficiencies in your day-to-day warehouse operations? In manual warehouse operations, mistakes are bound to happen – from misplacing items to inaccurate inventory counts, these errors can lead to wasted time, increased costs, and dissatisfied customers. However, warehouse automation solutions can revolutionize the way you manage your warehouse by automating mundane tasks with high accuracy and efficiency.

Warehouse automation allows you to streamline and optimize your day-to-day warehouse operations, such as inventory management and order fulfillment, through the use of logistics technology and machines. It eliminates the labor dependency for repetitive work and allows the staff to focus their efforts on more value-adding activities.

From robotics to AI-powered systems, the world of warehouse automation is constantly evolving. However, with so many options and products available today, navigating this complex landscape can be overwhelming for businesses seeking to implement the right solutions. Warehouse automation isn’t a one-and-done decision – it requires careful consideration and strategic planning. That is why, we will guide you about all the prevalent logistics support available in warehouse automation in this article so you can select the logistics solution that best fits your needs.

Top 10 technologies to achieve warehouse automation

- Automated multi-shift storage and picking systems

Automated multi-shift storage and picking systems are advanced warehouse automation solutions that leverage technology to optimize the storage and retrieval of products. These systems typically include high-density storage systems, such as AS/RS (Automated Storage and Retrieval Systems), and are capable of handling multiple shifts of order fulfillment.

With automated multi-shift storage and picking systems, products are stored in a dense and organized manner that maximizes the use of available space. This not only reduces the amount of space required for storage but also makes it easier and quicker to locate products when needed.

- Data analysis software

Data analysis software is an application that enables your business to collect and analyze data related to your warehouse operations. This data can include information on inventory levels, order fulfillment times, and employee productivity, among other metrics.

Your business can gain insights into the warehouse operations through the use of such software which will allow you to identify areas for improvement. For example, the software may identify bottlenecks in the fulfillment process or highlight products that are frequently out of stock. With this information, you can make data-driven decisions to optimize their operations and improve their bottom line.

- Optical recognition: scanning and identification of goods

Optical recognition refers to the use of technology to scan and identify goods within a warehouse. Optical recognition systems use cameras or scanners to capture images of products, which are then analyzed and matched to a database of known products. These systems automate the process of identifying goods and retrieving goods which reduces the risk of human error and improves the speed at which inventory is counted and tracked.

Optical recognition is a powerful tool for your business. Automation of the process of scanning and identifying goods will also reduce the costs associated with manual labor and improve the accuracy and efficiency of inventory management.

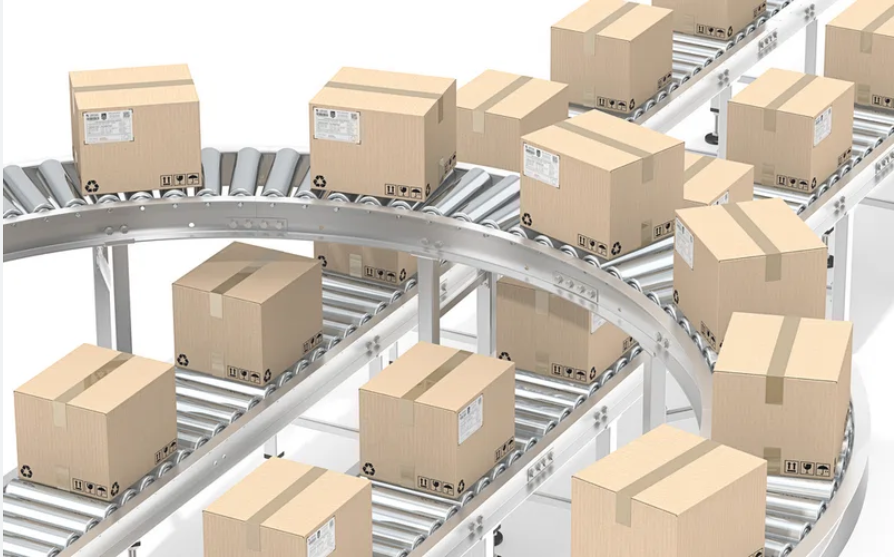

- Interconnected conveyor belts

Interconnected conveyor belts are a system of automated conveyor belts that are linked together to transport products and materials throughout a warehouse. These conveyor belts use sensors, controllers, and other automation technologies to move products and materials efficiently and safely.

In warehouse automation, interconnected conveyor belts are an important component of the material handling process. You can improve your warehouse efficiency and reduce the risk of human error by automating the movement of products and materials.

Interconnected conveyor belts can be integrated with other warehouse automation technologies, such as automated storage and retrieval systems (AS/RS), to create a seamless material handling process. This integration allows businesses to optimize their warehouse operations, reduce labor costs, and improve the accuracy and speed of order fulfillment.

- Warehouse Management Systems

Warehouse Management Systems (WMS) are software applications that help you to manage, control, and optimize your warehouse operations. These systems provide real-time visibility into inventory levels, storage locations, and order fulfillment status, allowing you to make informed decisions about how to allocate resources and fulfill orders efficiently.

WMS typically includes a range of features and functionalities, including inventory tracking, order management, shipping and receiving management, and labor management. These systems are usually integrated with other warehouse automation technologies, such as AS/RS and conveyor systems, to provide complete logistics support.

- Intelligent storage

Intelligent storage refers to a type of automated storage system that leverages advanced technologies, such as robotics, artificial intelligence, and machine learning, to optimize warehouse storage capacity and improve inventory management.

Intelligent storage systems typically consist of a combination of AS/RS, conveyor systems, and robotics. These systems work together to move products and materials efficiently within the warehouse and to store them in the most optimal locations based on factors such as product size, weight, and demand.

- 3D printing

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by layering materials, typically plastic or metal, in a specific pattern. This technology has gained significant popularity in recent years due to its versatility and ability to produce complex parts quickly and at a low cost.

3D printing can be used in warehouse automation to produce customized or replacement parts for automated material handling systems. This can reduce the lead time when you need replacement parts and minimize the need for manual labor in repairing or maintaining equipment.

- AGV (Automated Guided Vehicle) or AMR (Automated Mobile Robot)

Automated Guided Vehicles AGVs and AMRs are two types of warehouse automation technology that use mobile robots to move goods and materials around a warehouse or distribution center. AGVs are computer-controlled vehicles that are programmed to follow a specific path or route through a warehouse. They use a variety of sensors and control systems to navigate through the warehouse and can be used to transport goods between different areas of the warehouse, such as from storage racks to loading docks.

AMRs, on the other hand, are more adaptable than AGVs because they can move freely across a warehouse thanks to sophisticated sensors and algorithms. They are perfect for dynamic warehouse situations where layouts and workflows may change regularly because they can adjust to shifting layouts and barriers in real time.

- Smart glasses

Smart glasses are a type of wearable technology that can be used in warehouse automation to help operators pick orders more efficiently. They are equipped with a small computer and display screen, which can be used to provide operators with real-time information about the products. It’s like having a personal assistant right in your glasses!

By wearing smart glasses, operators can keep their hands free to pick and pack items, while still having access to all the information they need to complete their tasks. The glasses can even show product images, descriptions, and barcodes.

- Order picking robots

Order-picking robots, as the name implies, are robots that are equipped with cameras and software that allow them to navigate through the warehouse to pick and retrieve the products accurately and efficiently. These robots can be deployed as stand-alone intelligent machines for product retrieval or can also be used to assist operators in warehouses.

All the above-mentioned technologies can be integrated to provide complete warehouse automation or depending on your business’s unique requirements, some of these technologies may be more suitable than others. By evaluating your business’s specific needs and goals, Pterisglobal can help you determine which automation technologies are best suited to your operations and which will deliver the most significant ROI.

Factors to consider in the process of warehouse automation

In the quest for operational optimization and increased efficiency, warehouse automation has become an increasingly popular solution for businesses. And the vast variety of available warehouse technology can sometimes be overwhelming for businesses. Therefore, we highlighted the various factors that should be considered when implementing warehouse automation to ensure that the chosen solution is the right fit for your specific needs.

One important factor to consider is the potential reduction of labor costs and associated costs during labor shortages. Automated systems can help reduce the need for manual labor and potentially save on labor costs in the long run. It will allow you to ensure business continuity by reducing the dependency on labor.

However, it is important to take the potential for market fluctuations and company growth into account. The scalability of different automation solutions and their associated costs should be assessed to ensure that the chosen solution can adapt to changes in demand and accommodate growth. Pterisglobal offers after-sale services and scalability of its warehouse automation solutions to accommodate the growing needs of your warehouse operations.

Additionally, it’s important to consider potential changes to the automation infrastructure over time, such as relocation or redeployment, to accommodate evolving business needs. By carefully considering these factors, you can select the right warehouse automation solutions that suit your unique needs and offer a competitive advantage in the marketplace. However, we understand that selecting the right technology can be a complex and daunting process. Therefore, it’s essential to consider taking the services of a logistics provider who can guide and support your business through the process of selecting the right warehouse automation solution. Logistics providers have the necessary expertise and experience to evaluate businesses’ unique needs and recommend customized solutions that meet those needs.

At Pterisglobal, we take pride in being a globally integrated solution provider, offering customized system solutions for e-commerce logistics, express logistics, customized warehouse automation, airport logistics, and digital factory. With over 50 years of experience in the logistics industry, we have developed expertise in providing innovative solutions to meet our client’s unique requirements, no matter how demanding they may be. If you’re planning to automate your warehouse with the latest technology solutions on the market, we are the right team to help you. We offer a wide range of cutting-edge automation solutions that are customized to your specific needs, ensuring maximum efficiency and cost-effectiveness.

So, don’t hesitate to get in touch with us. Our team of experts is always ready to assist you and provide you with the best possible solution for your warehouse automation needs.