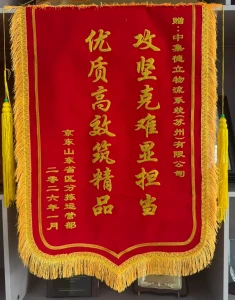

The highest form of validation in logistics automation is not found in general praise, but in the trust a client places in us to handle their most critical material handling challenges. Recently, CIMC Pteris was honored with a formal commendation from our Linyi Project client—a clear reflection of our customer-centric, problem-solving philosophy and our team’s ability to deliver system integration under pressure.

Behind this recognition lies a complex “dual-track” challenge: upgrading a high-capacity logistics hub in a brownfield environment, while maintaining 100% operational continuity. In an era where next-day and same-day delivery are the standards, there is no room for error in warehouse efficiency.

The Challenge: Complex Automated System Integration

The Linyi Project presented a high-stakes environment with two primary constraints for our automated sorting systems:

Heterogeneous Complex System Integration:

The scope required installing three automated steerable wheel inbound lines, two outbound lines, and one narrow-belt sorter, all while interfacing with dozens of data points across multiple third-party systems.

Zero-Downtime Mandate:

All upgrades had to occur without interrupting daily operations. Any misstep could have resulted in operational downtime and significant coordination costs. Like adding new instruments to a live orchestra without missing a beat, our work had to be perfectly synchronized with the client’s existing rhythm.

The Solution: Precision Engineering & Disciplined Execution

Guided by a strategy of “seamless system integration and disciplined execution,” CIMC Pteris delivered a tailored, end-to-end solution for this intelligent logistics upgrade:

Advanced Hardware Upgrades:

We deployed a comprehensive range of core material handling equipment, including belt conveyors, steerable wheel sorters, RFID systems, and AI-driven singulation systems, enabling full-process automation from infeed to loading.

Software & Capability Breakthroughs:

Our dedicated technical task force overcame cross-vendor compatibility issues, developing custom interfaces to bridge heterogeneous systems and eliminate data between old and new infrastructure.

Lean Project Execution:

From iterative design optimization and precise supply-chain coordination to structured on-site implementation, every phase was executed to maximize sorting efficiency and minimize risk.

The Result: Proven Success in Warehouse Continuity

The project was recently delivered on schedule and is now fully operational. We achieved two critical KPIs: seamless system integration and zero operational disruption. This upgrade provides the client with a scalable foundation to increase sorting efficiency and optimize labor costs, and future-proof their supply chain infrastructure.

Trust Earned, Responsibility Renewed

This recognition is more than a trophy; it is a reminder of our mission. At CIMC Pteris, we believe the best technology is the kind that solves real-world problems, and the best service is becoming a partner our clients can rely on with confidence. This commendation reinforces our mission to lead the intelligent logistics industry.

Looking ahead, we will continue to deepen our expertise in intelligent logistics, responding to every client’s trust with world-class execution and win-win results.