CIMC Pteris partnered with a leading express carrier to develop the Hangzhou Chengnan Smart Logistics Hub. By achieving a daily throughput of 2.2 million items with a 99.99% sorting accuracy, the project establishes a comprehensive, closed-loop automated operation. This solution not only solves the challenges of billion-parcel scale sorting but also sets a new benchmark for intelligent transformation within the industry.

01 Logistics Automation: A Must-Have for High-Quality Express Delivery Growth

In today’s global digital economy, the CEP industry is undergoing a profound transformation from a “labor-intensive” model to a “technology-intensive” one. As e-commerce demand continues to surge, the daily influx of hundreds of millions of parcels is straining traditional logistics frameworks. This is particularly evident during peak seasons, such as the “Double 11” shopping festival, where peak traffic can reach three times the daily average, exposing the critical efficiency bottlenecks and error risks of manual sorting. With rising labor costs and heightened service expectations, automation has shifted from an operational luxury to a strategic imperative for market competitiveness.

As a pioneer in technology-driven innovation, a leading Chinese express carrier has launched the Hangzhou Chengnan Smart Logistics Hub—a landmark project in this industrial transformation. Through a strategic partnership with CIMC Pteris, they have developed a logistics stronghold that integrates automation, intelligence, and high efficiency, setting a new industry benchmark for large-scale applications.

02 Chengnan Project: Reconfiguring Space for Large-Scale Smart Logistics

The Hangzhou Chengnan Smart Logistics Hub is planned with a total gross floor area of nearly 500,000 m². The phased implementation strategy enables efficient resource utilization while allowing benefits to be realized early in the project lifecycle.

- Phase I, with a floor area of approximately 200,000 m², was completed and commissioned in September 2022.

- Phase II, is scheduled for completion in 2025, further expanding the logistic hub’s logistics service capacity.

The logistics hub comprises six four-storey ramp-access high-standard warehouses, along with an office building and other supporting facilities. The ramp-access concept enables continuous multi-level vehicle circulation, significantly improving loading and unloading efficiency and optimizing site utilization.

Positioned as an ultra-large-scale smart logistics complex, the logistic hub not only supports traditional warehousing and distribution functions, but also integrates advanced warehousing, intelligent sorting, supply chain management, and regional distribution services.

03 Strong Partnership: Technology Empowerment by CIMC Pteris

For the automated warehousing and sorting system of the Hangzhou Chengnan project, the express carrier enterprise established a deep collaboration with CIMC Pteris.

CIMC Pteris has long been dedicated to the logistics automation industry, providing customers with end-to-end, full lifecycle solutions covering hardware (from core equipment to steel platforms and chutes), software (WCS/WMS), and services ranging from consulting and planning to project implementation and ongoing operations and maintenance.

In this collaboration, CIMC Pteris fully leveraged its expertise in large-scale automated sorting system integration, tailoring a comprehensive solution to meet the project’s massive scale and high throughput requirements, ensuring system stability and sustained high-efficiency output.

04 Systematic Technology Enablement: From Precise Execution to Intelligent Decision-Making

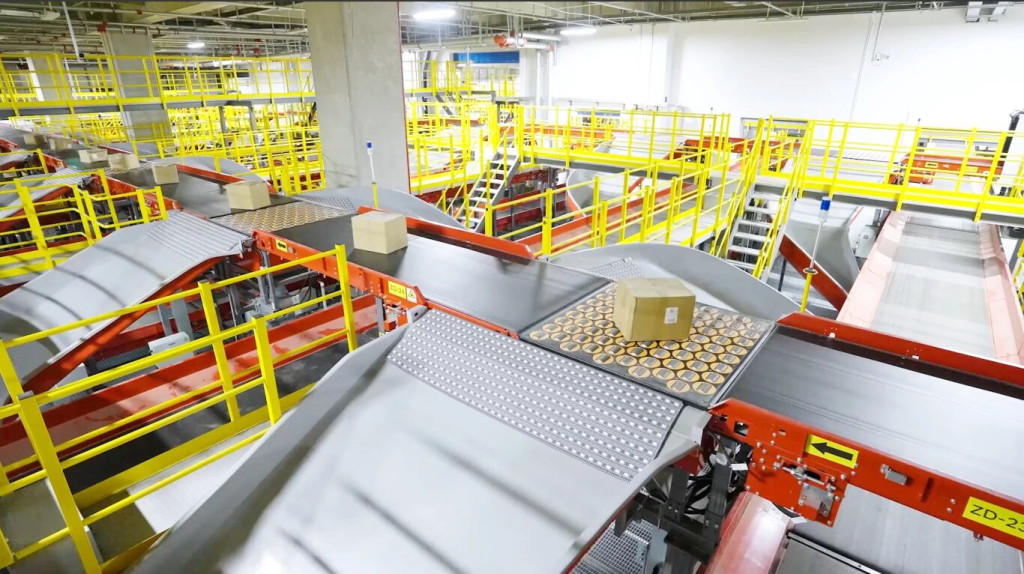

Phase I of the project is equipped with a comprehensive technical configuration, including 17 automatic inbound lines, 16 automatic outbound lines, 4 small-parcel feeding lines, 2 NC narrow-belt lines, and 4 small-parcel sorters, forming a complete automated sorting matrix covering multiple parcel types and operating scenarios.

Automated Sorting Network: Building a Highly Elastic and Adaptive “Intelligent Expressway”

To address challenges such as fluctuating parcel volumes and non-standard parcel specifications, the sorting network must offer elasticity and self-optimization capabilities. Through modular design, dynamic routing algorithms, and deep equipment coordination, the automated sorting system creates an “intelligent expressway” capable of adapting to business peaks and troughs

Core Sorting Capability: The Foundation for Large-Scale Processing

At the core of the system is a high-precision, highly reliable steerable wheel sorting system. Each line achieves a processing capacity of up to 6,300 parcels per hour, while the system’s overall peak throughput exceeds 107,100 parcels per hour. This capability provides a solid foundation for handling billion-scale parcel peaks during events such as “Double 11”, significantly reducing the marginal cost of large-scale processing.

Full-Scenario Coverage: Addressing Complex Parcel Handling Challenges

To accommodate the growing proportion of small parcels in e-commerce, the system deploys dedicated high-speed sorting equipment capable of handling 110,000 parcels per hour, effectively resolving industry challenges such as low efficiency and high error rates in manual small-parcel sorting.

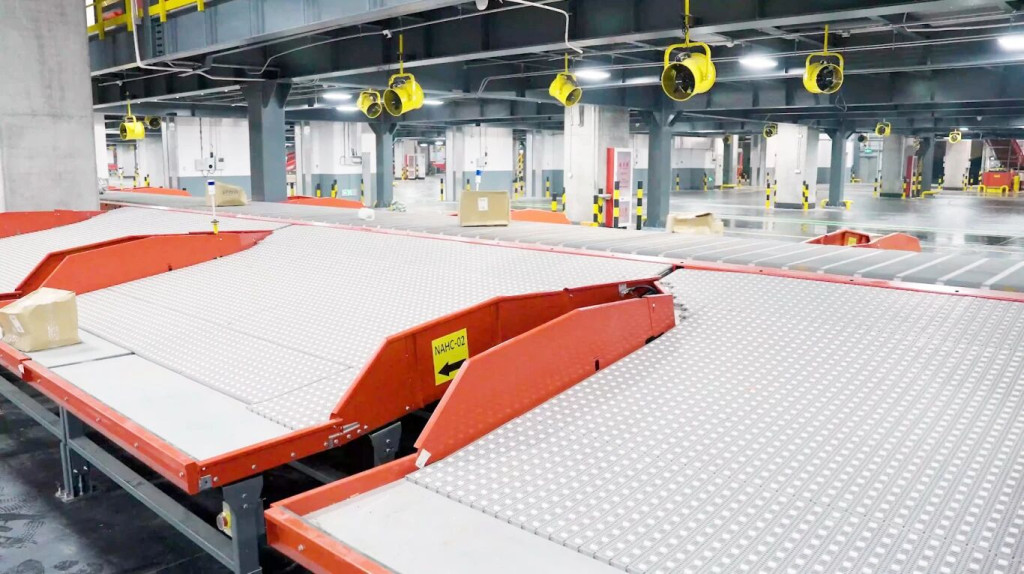

In addition, dedicated flexible handling lines (NC lines) ensure that irregular and overweight parcels are seamlessly integrated into the automated process, enabling a transition from partial automation to full-scenario automation and eliminating the need for extensive manual intervention.

Intelligent Identification and Decision-Making: A Data-Driven Transition from “Perception” to “Cognition”

Efficiency and accuracy depend on precise decision-making, which in turn relies on high-quality data. The system integrates AI vision recognition, dynamic DWS (dimension, weighing, scanning), and RFID technologies, building a real-time parcel data repository.

Beyond basic barcode capture, the system performs multi-dimensional sensing of parcel attributes, conditions, and potential anomalies—such as damaged labels or irregular shapes—within milliseconds. This provides a comprehensive data foundation for complex routing decisions and load balancing, enabling the system to evolve from passive execution to proactive optimization.

05 Intelligent Operational Closed Loop: From Process Automation to Operational Intelligence

The value of automation equipment is maximized only within a well-designed, continuously evolving operational closed loop. The intelligent operational loop established by this project embeds intelligent decision-making into every stage of material flow, driving a fundamental upgrade from process automation to operational intelligence.

Intelligent Pre-Processing: Creating a Structured Data Basis for Operations

After unloading, parcels are not simply fed onto conveyors. Instead, they must pass through standardized singulation and multi-technology integrated intelligent identification processes. This step is equivalent to issuing each parcel a unique and information-complete “digital identity card,” ensuring that the source data for all subsequent automated operations is 100% accurate and structured, thereby eliminating process disorder and efficiency losses caused by missing or incorrect information.

Precise Routing and Sorting: Orchestrated by a Central Control System

The warehouse control system (WCS), acting as the intelligent “brain,” performs millisecond-level calculations based on multi-dimensional information, including real-time parcel data, processing status of each line, and vehicle availability at loading docks. It dynamically commands execution units such as diverters and narrow-belt conveyors. Beyond routing parcels to the correct destinations, the system intelligently avoids congestion, balances line loads, and prioritizes urgent orders—realizing an upgrade from “fixed routing” to “dynamic optimal routing.”

Flexible Error Correction and Recirculation Mechanisms: Building a Highly Reliable “Safety Redundancy” System

Pursuing high accuracy requires response mechanisms for potential exceptions. The system’s built-in intelligent recirculation and manual verification mechanisms serve precisely as such “safety redundancy.” For the very small number of parcels that cannot be automatically processed due to label issues or special shapes, the system automatically guides them to human–machine collaboration workstations. Through self-diagnosis and flexible recovery, the system ensures flexibility and accuracy of the overall process while maintaining an extremely high level of automation.

06 99.99% Sorting Accuracy: Verified Performance Data

Following the commissioning of the Phase I automated sorting system at the Hangzhou Chengnan project, the system delivered a set of performance results verified through actual operation. In terms of sorting accuracy, all core indicators reached industry-leading levels:

- Automated parcel sorting system (H-type diverter):

Barcode reading rate ≥99%, successful sorting rate ≥99.99%

- NC single-item automatic sorting system:

Successful sorting rate ≥99.99%, system availability ≥99.5%

- Small-parcel automatic sorting system:

Barcode reading rate ≥99%, successful sorting rate ≥99.99%, system availability ≥99.5%

This means that among every 100,000 parcels, the number of sorting errors does not exceed one, significantly reducing after-sales costs and customer complaints caused by sorting errors, and substantially improving logistics service quality.

For the express delivery enterprise, the successful operation of the Hangzhou Chengnan project provides replicable and scalable practical experience for the development of its nationwide smart logistics network.

The implementation of this project establishes a full-process solution covering equipment development, system integration, and operational maintenance, serving as a benchmark example driving the logistics industry’s transformation from labor-intensive to technology-intensive operations.

Looking ahead, China’s 15th Five-Year Plan has set higher requirements for the development of smart logistics. Taking the Hangzhou Chengnan project as a new starting point, CIMC Pteris will continue to deepen its commitment to independent technology research and development, promoting the localization, standardization, and large-scale application of logistics automation equipment. This will not only help logistics enterprises reduce costs and improve efficiency, but also strengthen the foundation for the independent and controllable development of China’s smart logistics industry, injecting sustained momentum into the construction of a modern logistics system and the high-quality development of the real economy.

Original link:【案例速递】中集德立:以99.99%分拣准确率破解亿级包裹难题