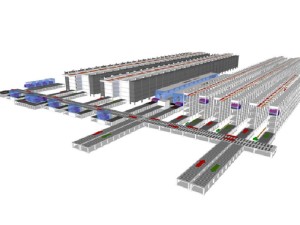

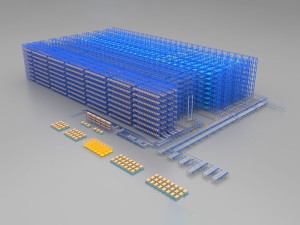

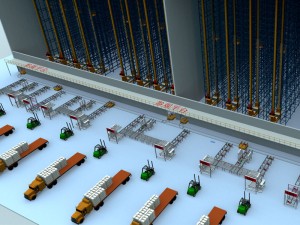

Application method: According to the cargo throughput of the three-dimensional warehouse, the shuttle carrier is arranged at one end location of the warehouse. By hoisting, the system realizes the optimal space usage rate and places goods between different levels/heights of the warehouse.

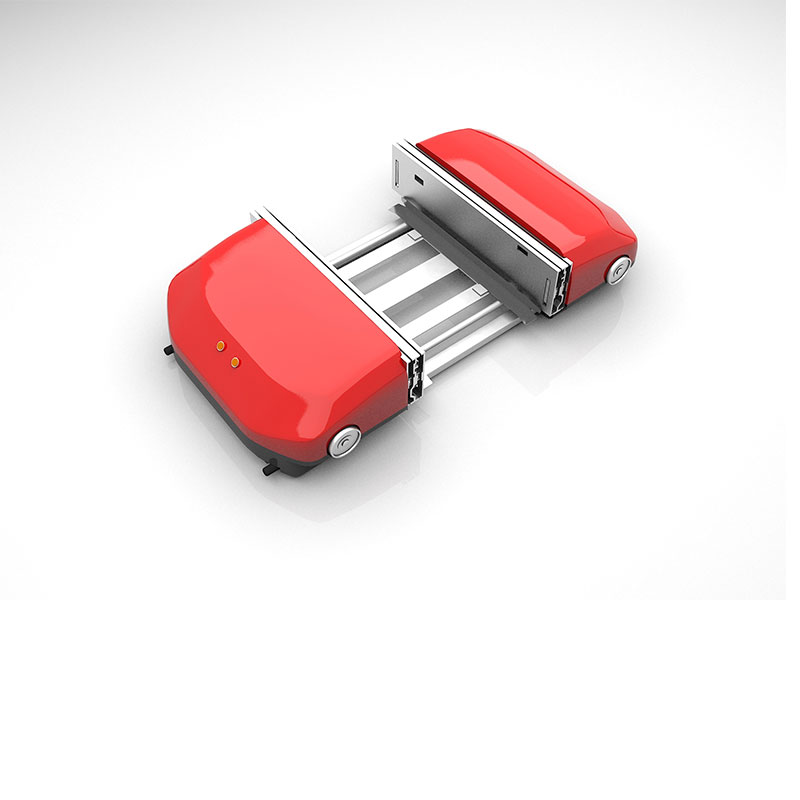

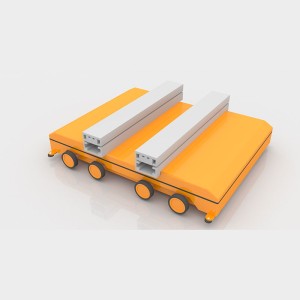

Multi-layer shuttle system

Description

Descripition

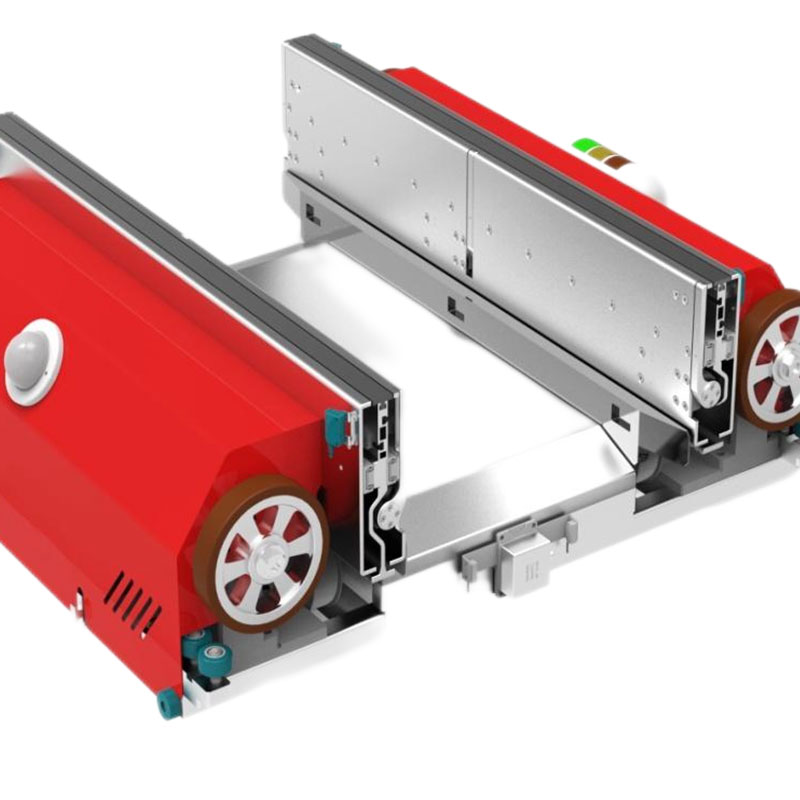

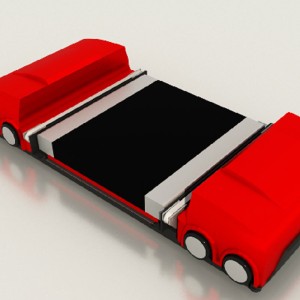

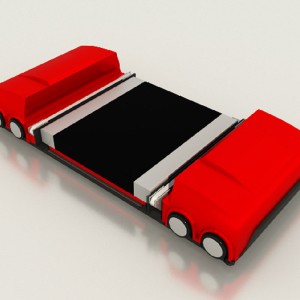

Specification

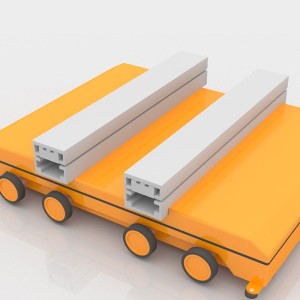

Solutions

Case

Application Method:

According to the cargo throughput of the three-dimensional warehouse, the shuttle carrier is arranged at one end location of the warehouse. By hoisting, the system realizes the optimal space usage rate and places goods between different levels/heights of the warehouse.

| Specification | |

Max: | 600*465*600(MM) |

Min: | 200*150*100(MM) |

Item weight: | ≤50KG |

Item size: | 1330*970*300 (MM) |

Passage width: | 1010(MM) |

Battery capacity | Lithium iron phosphate charge 2~3h endurance 6~8h |

Equipment weight | 450kg |

Warehouse Automation System Solutions

With the rapid development of the enterprise, the variety of products, and the accelerated turnover of material storage, the logistics and storage space of the enterprise is beginning to be tight. Therefore, various material storage projects have become an inevitable measure for enterprises to improve efficiency and core competitiveness. PGSL merged into the airport logistics sector of CIMC Group through reverse acquisition, integrated CIMC Group’s warehousing project resources and products, and provided customers with a package of logistics and warehousing solutions.

Yulong Petrochemical

-The total operating time reaches 144 hours under normal operating conditions.

-At least 72 hours of warehousing peak test is included.

-The equipment failure rate is 5 % and the system error rate is 5 %.

-The project includes WMS system, intelligent warehouse control system, intelligent warehouse dispatching system, etc.

New energy industry — BYD

A total of 5 detection lines are designed, each line has four operating links, cover removal, OCV detection, heat sealing and cover. Overall planning scheme There is no crossing of logistics and flow of people and no repeated return-paths, which can be controlled by the system in an orderly manner.