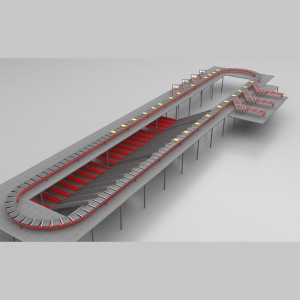

Application method:Cimc – type high – speed ring sorter has flexible layout, simple installation and convenient debugging. The new sorter technology greatly increases the energy efficiency of the equipment, fully embodies its environmental advantages, and minimizes the product life cycle cost.

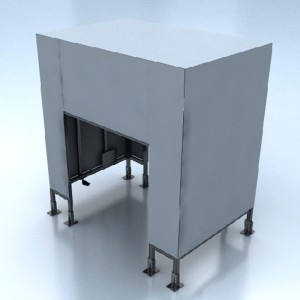

Flip sorter

Description

Descripition

Specification

Solutions

Case

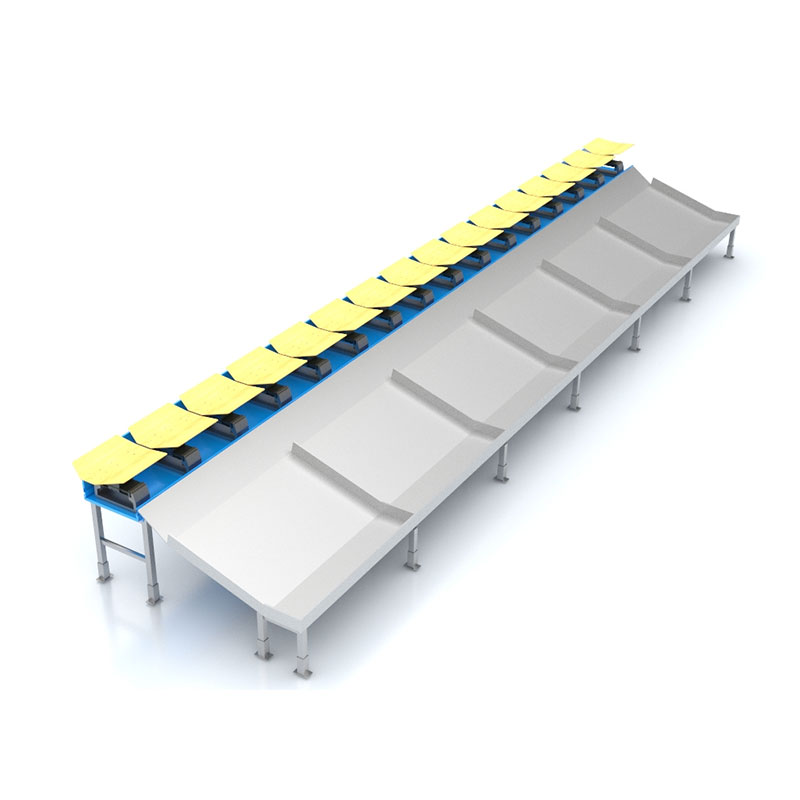

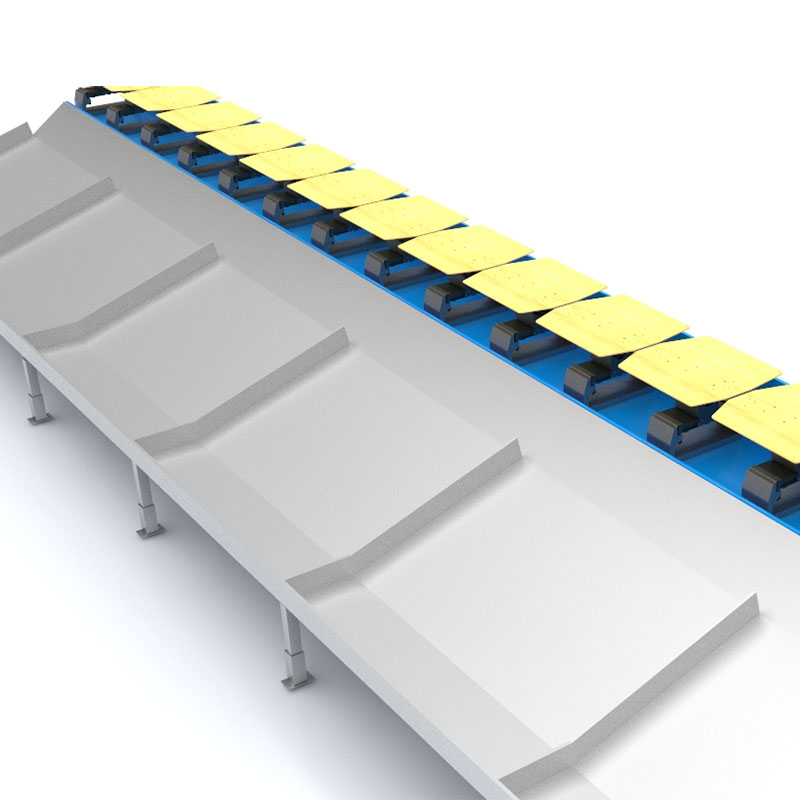

Application Method:

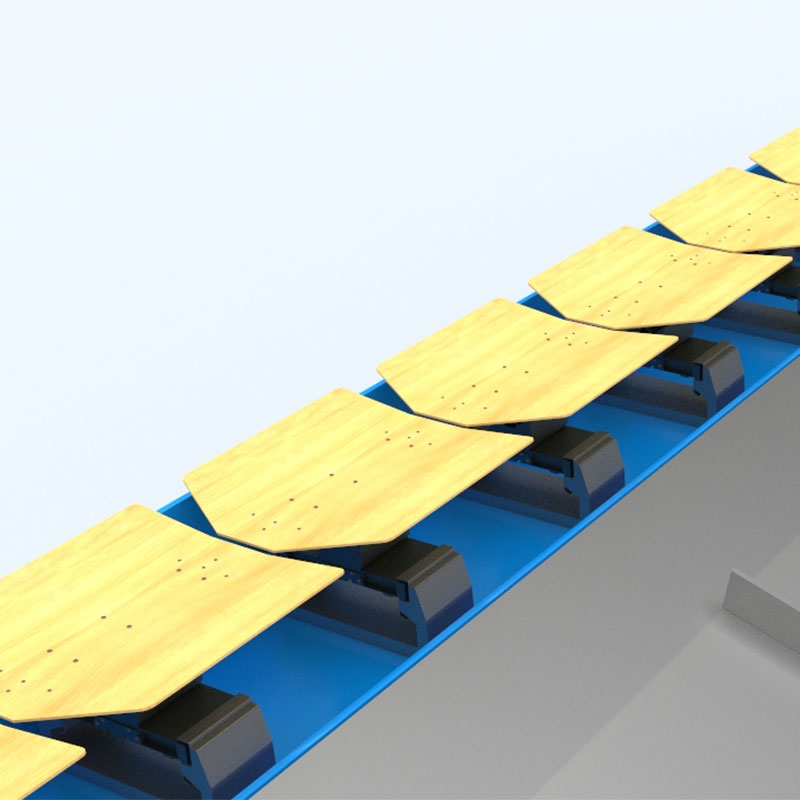

A single pallet is loaded with a single cargo, and the cargo is distributed through the scanning equipment. When the cargo reaches the corresponding grid port, the tilting motor turns over and drives the pallet to tip over to the corresponding grid port. The cargo slides down from the pallet and enters the corresponding grid port.

Features of the Flip Sorter

- Automation:Flip Sorter automates baggage sorting, tracking, and identification to reduce labor costs and increase efficiency.

- Efficient:Flip Sorter’s flexible layout makes baggage sorting more accurate and faster.

- Adaptable:Flip Sorter is suitable for sorting baggage of different sizes and shapes in airports, logistics centers, etc., and is highly versatile and flexible.

Flip Sorter is an efficient automated logistics equipment. The above are the core advantages of Flip Sorter.

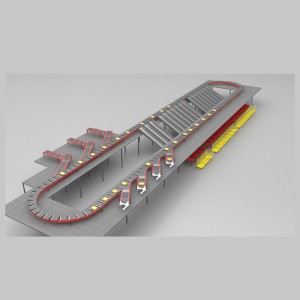

Application Scenarios of the Flip Sorter

- Airport baggage sorting: Flip sorter can automatically sort, identify, and track passenger baggage and sort baggage into different flight check-in vehicles, thus ensuring no baggage mix-up for each flight and improving the efficiency and accuracy of baggage sorting.

- Logistics and warehousing locations: Flip sorter can sort goods into different transport vehicles, resulting in faster and more accurate cargo logistics.

| Specification | |

| Drive mode | linear motor |

| Sorting speed | up to 3m/s |

| Sorting method | one side or two side |

| Noise level | 62db |

| Maximum length of a single pallet | 1000mm |

| Maximum length of double pallet cargo | 1600mm |

| Maximum width of goods | 1000mm |

| Standard cargo weight | 50KG |

| Enhanced cargo weight | 60KG |

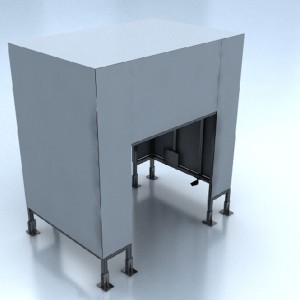

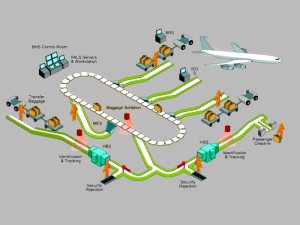

Airport Logistics System

With more than 30 years’ experience in aviation equipment manufacturing, and combining the latest global technologies, the automatic baggage handling system is developed independently. The system includes the equipment of check-in, collection, transportation, identification, sortation, temporary storage, reclaim and etc. By integration of electromechanical, control, coding, network and information systems, it can meet the complete processes of baggage departure, arrival, transit storage and etc. PGSL strives to be the best in its core skills, that is, to create value for customers by providing engineering solutions of the highest quality and highest standards.

Beijing Daxing Airport

The gift project for the 70th anniversary of the founding of the People’s Republic of China in 2019, designed cargo throughput of 600,000 tons/year, covers an area of 77,000 square meters, including International cargo Station No. 1 warehouse, International Cargo Station No. 2 warehouse, International Cargo Station No. 3 warehouse, domestic cargo station.

Pudong Eastern Airlines Cargo Depot

Shanghai single largest freight terminal, designed cargo throughput of 1.2 million tons/year, covers an area of 85,000 square meters.